woodworking homemade shopmade craft

Homemade Wood Lathe

I decided to build the wood lathe. The main articles which I make are not turned usually. I case it is necessary, I used the metal lathe or motor drill and sanding block etc. However, the metal lathe suddenly stopped for the motor failure. I have repeatedly fixed up the motor but at this time it is completely broken. The replaceable motor is not available. Therefore, I thought to make a pulley which can be installed together with the chuck to drive the spindle.

The power drill is replaced with the original motor, adding the reverse rotation switch. Speed control is by variable transformer resulting all the gears are removed.

I bought this metal lathe from Taiwan by personal import around 2,30 years ago when JYen was very strong and hobby lathe was too expensive. Anyway, quality was terrible, but anyway I could use.

Anyway I needed the wood lathe to make the pulley to drive the metal lace. However I have no space to put such a large lathe in my shop,. This is another reason why I have not made the wood lathe. Estimated size would be around 1m in total length.

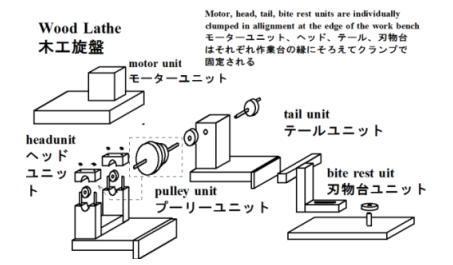

I designed the lathe, the units of this lathe, i.e. the head stock, tail stock, bite rest, motor unit individually and align at the edge of the work bench. These units can be contained in a small box to store even in my shop. Accuracy will be not so good, but I do not care as my skill is not so accurate.

I used scrap wood, and the motor from junk cleaning machine.

The above is the whole arrangement. I hope you can image. Completed lathe is:

like this. I can put them in a small box to store in a small space. I think it is the good design for the small shop owners.

When the lathe is used, units are set as shown above. It has L,M.S sized 3 pulleys to change the rotating speed. Of cause motor unit position is changed according to the rotation speed. No need to say, the motor unit is clumped at the another side edge of the work bench.

The bite rest is put to turn various shape and size.

The dead end of the tail stock is 12mm bolt, an end is sharpened to push the work and fixed by a lock nut plate.

Accuracy is much better than estimated. This wood lathe works well better than I estimated, therefore, I changed my mind and will make same items such as the tops, cup and ball etc. I can turn the wood block, branch, twig etc. which I can get on daily walk.

Turning the pulley for metal lathe drive.

This is the metal lathe driven by new wood pulley and power drill unit.

This is the column of newly made(making now) globe. I will show the globe on this site when completed.

I tried to use this machine by turning a wood piece.

This is a tree branch which I got on way of my daily working. Diameter is about 60mm. I turn this material on the lathe.

I cut the branch in suitable length.

Removing the bark.

Completely debarked.

Setting this piece on the lathe. Shop made chuck is used, but it would be not necessary, I thought.

Following video shows turning. Cutters are the chizel, wood file, curving knife. After cutting, I will finish by sanding.

There is no problem for the work. However, this chuck must be a little more improved.

This shows half done work. I decided to make a Kokeshi doll, Japanese traditional turned wooden doll. However the completed kokeshi is not cute, but something horrible which you might have seen in your nightmare. But, anyway, this wood lathe works well better than I thought.

The following comments are what I thought on this project.

1) The reason why I made this lathe as individual units are combined taking alignment at the edge of the work bench is only one, i.e. small size to store. Therefore this lathe has no base nor rail to align the center. Therefore accuracy is not perfect, but it is acceptable for my use. If I need more accurate work, I use the metal lathe.

2) I used a junk motor of the cleaning machine in my junk box. Many people use the power drill for the self made lathe. It is easy to assemble, but power drill runs too fast for my use and cleaning machine motor is better, I believe. The main reason is that I had this motor already. I onece used this for the desk top band saw.

3) Alignment of center shaft and tail stock dead center is very important. If it is not aligned well, parallelism of the work is not good. But in case of this lathe, all the unit is aligned at the edge of the work bench. I think it is good enough for use. In my case, staff made by this lathe is better than I expected.

4) This lathe has turn the very long work. Approximately. 300 or 500 mm would be possible.

5) I used only the scrap wood pieces in my garbage box, junk metal rod, used bearing etc. Therefore I bought nothing for this project. New material of hard wood is tremendously expensive in Japan, I have no skill, I have no good machines, therefore I designed and made within my possibility. This lathe looks like junk, but works well. I am satisfied.

6) I use now only a simple face plate, but now making a chuck.

7) I used the bearings as I had them. But hard wood block is useable. Driving pulley is between the bearings which removable so that the belt can be replaced.

8) I just started to use. So far this lathe is good, better than I expected. However if necessary, I will improve, but if improvement is necessary, my skill is improved. Then I will build a new lathe.

article index

return to home